Arc Flash Alert: The ONE Die Compatibility Check You MUST Make When Sourcing Alternative Power Lugs

T: The Thesis—Why Die Compatibility Is Non-Negotiable

In high-current electrical systems—from Energy Storage Systems (ESS) to industrial panels—a faulty crimp connection is not a matter of inconvenience; it is a precursor to arc flash, catastrophic failure, and regulatory non-compliance 1. When engineers and procurement managers transition from an incumbent supplier to an alternative power lug source to mitigate supply chain risk or reduce cost, the single most critical failure point is often overlooked: The compatibility between the new lug and the existing crimping die.

The Arc Flash Hazard Analysis Yourself

Crimping is a carefully engineered solution, a process of “cold forging” the conductor and the terminal barrel into one homogeneous metal mass 2, 3. This delicate process is not controlled by the expensive hydraulic tool itself, but by the precise dimensions of the crimping die. If the die does not match the lug’s specific wall thickness and material, the electrical connection will fail, regardless of the lug’s quality.

E: Expansion 1 – The Engineering of Failure: Why the Die is the Critical Link

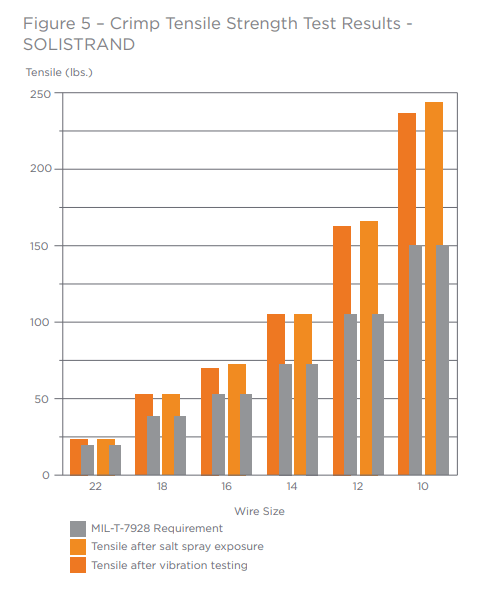

The integrity of a high-current compression lug hinges on achieving the correct compression ratio. The crimping die is responsible for creating a specific crimp profile (crimp height and crimp width) that optimizes both the mechanical and electrical performance of the connection .

The Physics of a Bad Crimp

If the die is mismatched, it leads to two primary failure modes, both of which accelerate resistance and thermal runaway:

- Under Crimped (Too Loose): The die fails to fully compress the conductor. This leaves numerous air gaps within the barrel, leading to increased electrical resistance . High resistance generates excessive heat, which can accelerate the degradation of the connection interface and cause system failure 5.

- Over Crimped (Too Tight): The die compresses the material excessively. This severely damages the wire strands and the terminal body itself, causing a reduction in the crimp tensile strength . It can also cause “winging” of the metal where the dies meet, compromising the mechanical seal .

A proper crimp achieves a homogeneous mass, maximizing conductivity and tensile strength 3. A crimp that is too loose or too tight will cause electrical discontinuity, cracking, or breaking under mechanical stress 2.

E: Expansion 2 – The Mandatory Check

Switching suppliers introduces inevitable tolerance differences. The only way to guarantee a reliable, compliant termination when sourcing an alternative lug is through a methodical cross-reference and physical verification.

Actionable Check: Die Index Matching

The entire UL/CSA compliance system relies on the traceability of the crimping process. For a compression lug to maintain its certification, it must be crimped using the tool and die specified by the manufacturer 6.

- Identify the Die Index: High-end compression lugs are often color-coded and marked with a specific Die Index Number 7. This number is the DNA of the crimp profile required for that specific lug size and material.

- Verify the Embossment: After the crimp cycle is complete, the final, non-negotiable step is inspection (https://www.youtube.com/watch?v=WwQK-60qEQU). The embossment left by the die on the connector must visually match the Die Index marked on the connector 8, . This confirms that the correct die and compression force were applied .

- Physical Measurement: For the highest level of assurance, technicians should use a vernier caliper to measure the final “Across the Flat” (AF) dimension of the hexagonal crimp. This measured compaction should match the AF of the die (typically within ) .

Failure to perform this verification when using an alternative lug can void the safety rating and place the entire installation at risk of failing mandatory UL 486 requirements 9.

A: Authority and Application in High-Current Systems

The criticality of die compatibility is exponentially higher in applications dealing with high power, where a minor increase in resistance translates directly into severe heat.

The Role of Regulatory Standards

- UL 486A-B: This tri-national safety standard mandates the mechanical strength and electrical conductivity requirements for wire connectors 10, 11. Any termination that uses an unmatched die fails to meet the safety and reliability requirements dictated by this benchmark.

- IEC 61238-1: This international standard specifies stringent test methods, including mechanical and electrical tests, required for compression connectors in power cables 12, 13.

Complex Applications Demand Precision

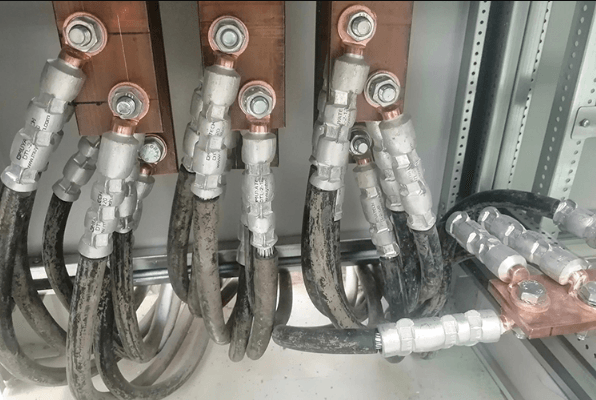

The challenges multiply in complex, high-growth applications like EV, Solar, and ESS:

- Bi-Metallic Lugs and Creep: When connecting copper and aluminum cables, bi-metallic lugs are necessary to prevent galvanic corrosion . Since aluminum has a 35% greater coefficient of thermal expansion than copper 14, the die must be precisely engineered to control the compression and prevent “creep” (loosening of the connection interface) and eventual failure 15.

- Heavy-Duty Requirements: Heavy-duty power lugs, often used for critical battery connections, have a wider and 80% heavier wall than standard lugs of the same gauge . This thicker material requires specialized dies and calibrated tools Using an unapproved die on these thicker lugs will result in an ineffective crimp and compromise the system’s ability to handle high currents.

Final Verdict: When sourcing alternative power lugs, the decision cannot stop at visual inspection or datasheet comparison. The integrity of your connection—and the safety of your installation—is determined by the compatibility of the alternative lug with your existing crimp die index. Verifying this match is the single most important action to transition safely, maintain compliance, and avoid the catastrophic failure signified by an Arc Flash Alert.