BESS Connector Reliability: Cold-Forged Lugs Mitigate Thermal Runaway in 1000V DC Systems (UL 486 & TCO Analysis)

Abstract: In the 20-30 year lifecycle of a Battery Energy Storage System (BESS), cable lugs function as critical energy transmission joints, where their conductivity and mechanical stability directly determine the system’s safety margins. Facing 1000V high-voltage conditions and daily temperature fluctuations, traditional connecting solutions often experience unsafe temperature rises due to excessive contact resistance, which is a potential trigger for the thermal runaway cascade. Standards like UL 486E and IEC 61238 validate that using cold-forged terminals with optimized grain structure can reduce the voltage drop by 47%, yielding a 20-year operational cost that is only one-third of that associated with cast-process components. This guide leverages thermodynamic modeling, empirical conductivity validation, and Total Cost of Ownership (TCO) assessment to reveal the strategic value of high-specification cable lugs in BESS system engineering.

I. Thermodynamic Challenges in High-Voltage Environments

In the 20-30 year operational lifespan of a BESS, the line lug serves as a critical junction for energy transfer. Its thermodynamic stability is essential for maintaining the system’s safety margin. When current density exceeds 150 A/mm², just a increase in the connection point’s contact resistance can cause the local temperature rise () to breach the 60K threshold, acting as a core initiator for the thermal runaway chain reaction.

1.1. The Thermal Runaway Cascade Mechanism

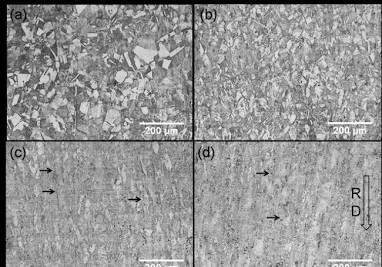

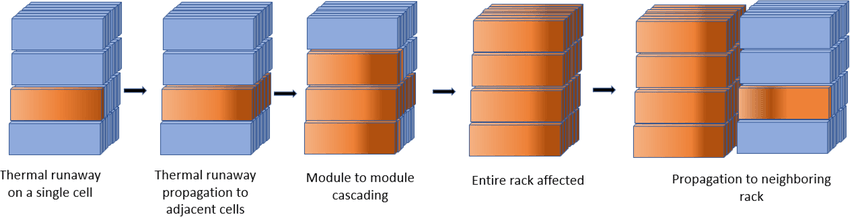

Thermal runaway is fundamentally the establishment of a positive feedback loop, characterized by distinct evolutionary stages:

- Initial Stage: Frictional wear at the contact surfaces reduces the effective conductive area, consistent with the Holm contact resistance formula (where is the actual contact radius).

- Accelerated Stage: When the temperature rise exceeds the copper-tin plating’s eutectic temperature (228°C), the Intermetallic Compound (IMC) layer growth accelerates rapidly.

- Critical Breakthrough: If the local temperature reaches 500°C, electrolyte vapor ignites upon encountering an electric arc, establishing an irreversible thermal-electrical coupling failure.

The US UL 1973 standard mandates that connectors must safely carry 125% of the rated current in an 85°C ambient environment. This requires the lug design to satisfy a stringent temperature rise limit (). Failure analysis reveals that conventional cast lugs experience resistance fluctuations 3–5 times greater than those of cold-forged components, due to micro-porosity along the grain boundaries.

1.2. Arc Flash Protection Standards for 1000V DC Systems

Under 1000V DC busbar voltage, breaking the circuit can produce a persistent arc up to 40mm long. IEC 61439-2 mandates the following protection levels:

点击添加内容