Circular Connectors: Classification, Standards, Applications & Replacement Guide | Aerospace, Military & Industrial Use

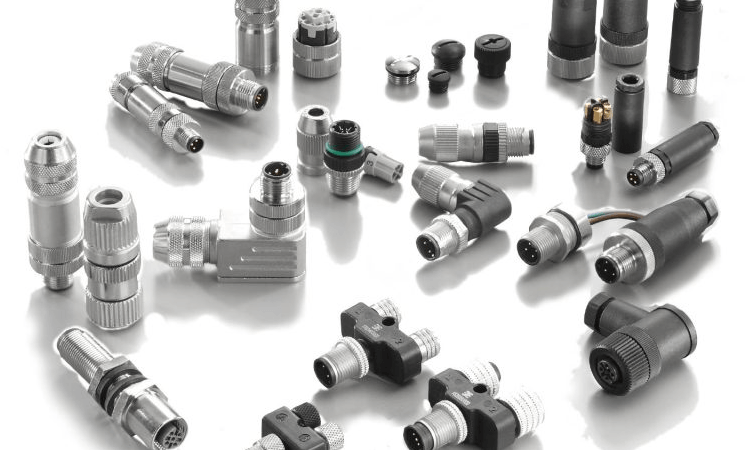

Aviation plugs, also known as circular connectors, are mainly cylindrical pin electrical connectors. Their English name is “Circular Connector”.

Classification of Aviation Plugs

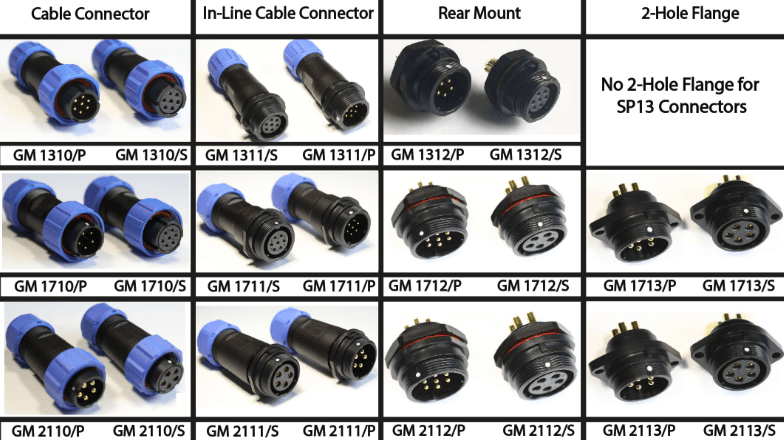

- Classification by the Number of Pins: Usually, each end of an aviation plug has three, six, or eight pins.

- Classification by Manufacturing Specifications, Size, Connection Angle, and Connection/Disconnection Mode: According to manufacturing specifications, aviation plugs can be divided into different types. They also come in various sizes, such as M12, M8, M5, M16, 5/8′, M23, and 7/8′, which are commonly used in non-standard automation. In terms of connection angle and connection/disconnection mode, there are different designs to meet various application requirements.

Standards for Aviation Plugs

- German Standard Aviation Plugs: The DIN standard is set by the Deutsches Institut für Normung (DIN), the German national standardization agency. DIN aviation plugs comply with German electrical standards and have high-frequency functions and iconic features, such as protective metal shells and round terminals with notches. This structure ensures they are correctly paired. For more information, please refer to the official website of DIN (https://www.din.de/).

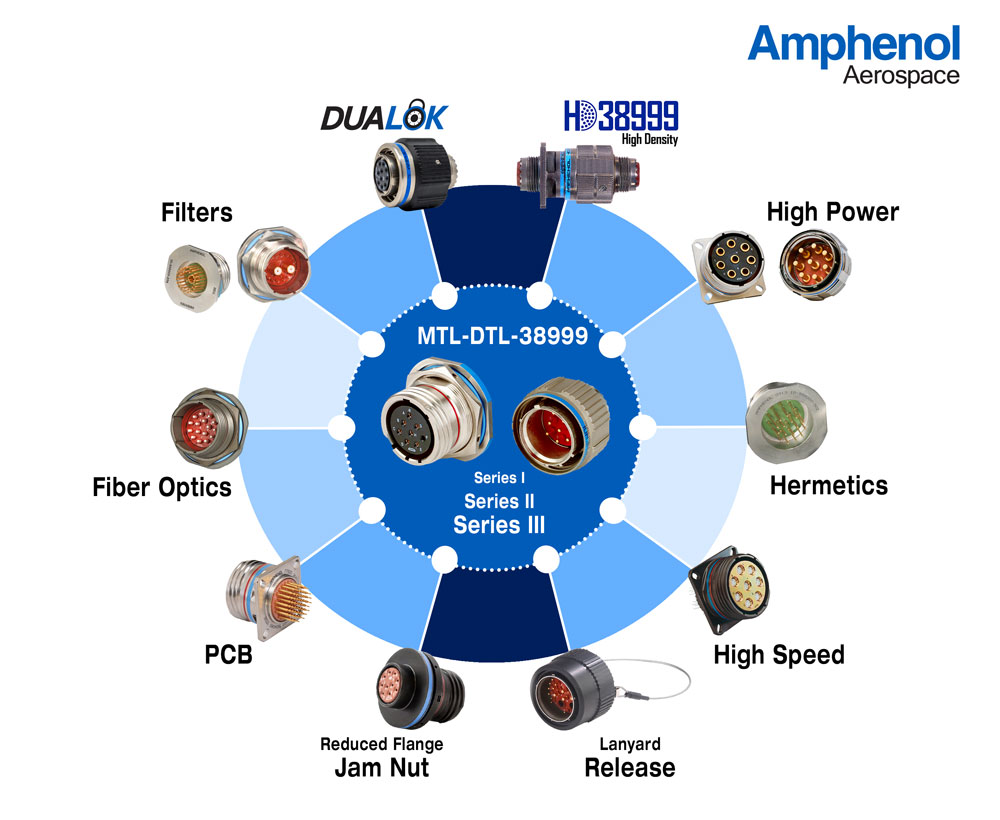

- US Military Standard Aviation Plugs: MIL-Spec connectors are designed based on the best practices for military and aerospace applications. These rugged connectors are ideal for high-impact use and are highly resistant to extreme environments. Due to the epoxy seal around the terminals, some MIL connectors are actually sealed or hermetic, and most of them are waterproof. You can learn more about MIL-Spec connectors on the website of Monroeaerospace (https://monroeaerospace.com/blog/comparison-of-the-5-classes-of-an-connectors/).

- Micro and Nano Aviation Plugs: Micro and nano aviation plugs have smaller pin and hole diameters and more closely spaced contacts. This helps save surface space on the terminal surface and reduces the additional weight of the connector to the components.

Connection Methods and Advantages of Aviation Plug Terminals

- Connection Methods: Like most types of electrical connectors, aviation plugs have various connection methods, including insulation displacement, soldering, winding, screw or lug connection, and pressure connection. Circular aviation plugs come in a variety of contact sizes and housing sizes, ranging from M8/M5/M12 to M12/M16, depending on the specific purpose of the connection. Smaller housing diameters are used for sensors and other precision and high-sensitivity applications, while larger housing diameters are used for power transmission, such as in agricultural machinery.

- Advantages

- They are an ideal choice for applications that require electrical connectors with more robust terminals. Their cylindrical shape makes them particularly resistant to mechanical turbulence and impact.

- They have excellent waterproof, moisture-proof, rain-proof, sun-proof, and corrosion-resistant properties.

- They are flame-retardant, anti-oxidant, and environmentally friendly, as all products come from green production lines.

- They simplify the assembly process and mass production process, improving production efficiency.

- They are easy to maintain. There is no need to cut cables, electrical plastic sheaths, etc. In case of a failure, simply rotate the two ends of the waterproof joint, which is convenient for the maintenance of waterproof products such as LED, solar energy, and geothermal energy.

- They improve the flexibility of design. Using connectors allows engineers to design and integrate new products more flexibly when using components to form a system.

Applications of Aviation Plugs

- Aerospace Field: Due to their reliability and durability, aviation plugs can work in high-altitude, high-speed, high-temperature, and low-temperature environments and maintain good electrical and mechanical performance. In addition, because of their waterproof, dustproof, and corrosion-resistant properties, they can be used in various harsh environments. For more information about aviation plug applications in the aerospace field, you can refer to the ISO official website (https://www.iso.org/obp/ui/#!iso:std:6675:en).

- Military Field: Aviation plugs are an important part of the military field. They are widely used between the electronic devices of military equipment such as tanks, warships, and aircraft. Their reliability and durability ensure the reliability of information transmission and the effectiveness of equipment in a war environment. Also, their waterproof, dustproof, and corrosion-resistant properties enable them to adapt to various harsh war environments.

- Industrial Field: Aviation plugs play an important role in many important industrial fields, such as factory automation equipment, where they are used to connect sensors and control systems to ensure accurate data transmission. They are also used in the petroleum, chemical, and heavy industry fields.

Figure-2-Different-Models-of-INTE-AUTO-Waterproof-Aviation-Connectors

Replacement Cycle of Aviation Plugs

The replacement cycle of plugs should generally be evaluated according to the actual usage situation. Here are some recommended considerations:

- Regularly check the performance of aviation plugs, including indicators such as transmission speed, contact resistance, and insulation resistance. When the performance deteriorates or does not meet the requirements, consider replacing the plug immediately.

- Regularly record the usage time and the number of insertions and removals of the plug to evaluate its wear degree. When the usage time or the number of insertions and removals reaches the expected value, consider replacing the plug.

The service life of aviation plugs is affected by various factors. In a harsh flight environment, aviation plugs may be affected by factors such as temperature, humidity, and vibration, thereby reducing their performance. Especially in extreme temperatures or humidity, the plug material may expand or contract, reducing the matching accuracy of the pins and sockets. Frequent insertion and removal of the socket may wear the socket pins and the socket, reducing the contact performance of the connector. Over time, the metal inside the socket will also wear, affecting its service life. Therefore, regular maintenance and upkeep can help extend the service life of aviation plugs.

When replacing aviation plugs, the following points should be noted:

- Ensure that the new plug matches or is compatible with the original model to ensure that the new plug can meet the requirements of the system.

- Before replacement, make sure the equipment is completely powered off to prevent electrical accidents.

- When installing the new plug, follow the manufacturer’s instructions to ensure that the socket and plug are aligned and use the appropriate tools to fix them.

- After installation, carry out necessary performance tests to determine whether the new plug is working properly.