Cold-Forged vs. Cast Lugs: The TCO Difference That Prevents Thermal Runaway in Battery Systems

The humble terminal lug is, counterintuitively, the weakest link in high-capacity Battery Energy Storage Systems (BESS). Over the system’s 20–30 year lifecycle, this critical component must endure 1000V DC and thousands of daily thermal cycles. When conventional casting methods are used, the resulting substandard contact resistance leads to dangerous temperature rise—the primary latent trigger for catastrophic thermal runaway[1].

This is why cold-forged copper terminals are a strategic necessity. Verification under UL 486 and IEC 61238 standards consistently demonstrates that adopting cold-forged technology dramatically enhances system stability, ultimately reducing the Total Cost of Ownership (TCO) by over 30% compared to traditional cast methods.

1. The Unacceptable Risk: Thermal Runaway and the Limits of Cast Lugs

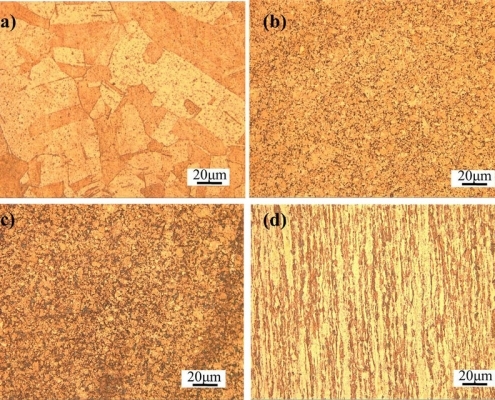

For utility-scale BESS, safety begins with thermal management at the connection point. When local current density pushes limits, even minor contact resistance causes localized temperature spikes that breach the mandatory T<30K temperature rise limit required by standards like UL 1973.

The Thermal Chain Reaction

Failure is a cyclical process:

- Initial Stage: Wear and movement reduce the effective conductive area.

- Accelerated Stage: Excessive heat surpasses the copper-tin plating eutectic temperature (~228°C), causing Intermetallic Compounds (IMC) to proliferate, rapidly increasing resistance[2].

- Critical Failure: Local temperatures reach a tipping point, initiating electrolyte ignition and system breakdown.

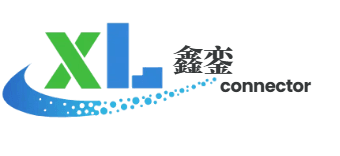

Traditional cast lugs are structurally compromised by large grain sizes and microscopic porosity, making them inherently prone to resistance instability. Cold forging, however, uses plastic deformation to refine the copper grain structure to below 10m. This dense, fine-grained structure is the foundational defense against resistance buildup.

2. Engineering Superiority: The Cold-Forged Advantage

The difference between cast and cold-forged technology translates directly into hard, verifiable metrics—the ultimate proof of performance.

Crystalline Structure and Quantified Gains

The structural density of cold-forged T2 copper yields significant measurable improvements:

| Performance Metric | Traditional Cast Copper | T2 Cold-Forged Copper | Improvement |

|---|---|---|---|

| Conductivity (IACS%) | 98% | 101% | +3.06% |

| Tensile Strength (MPa) | 220 | 380 | +72.7% |

| Thermal Stability | High Fluctuation | Low Fluctuation | 28.9% Lower Temperature Rise |

This superior performance is confirmed under rigorous testing. Cold-forged solutions achieve dynamic stability (resistance change 3% after 2000 thermal cycles) and maintain high DC arc impedance[1], essential for 1000V DC systems.

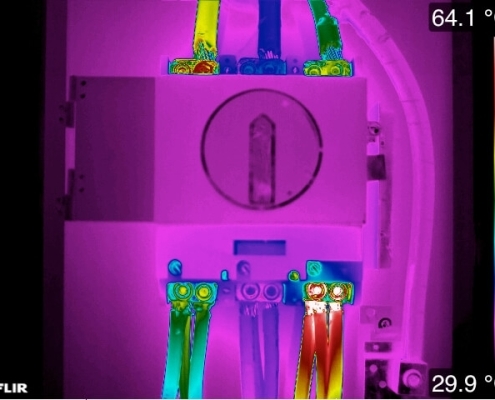

Advanced Solutions for Complex Wiring

In BESS, connectivity challenges go beyond copper density:

- Friction Welding for Bi-Metallic Systems: Connecting copper and aluminum requires preventing galvanic corrosion[3]. Advanced friction welding controls the copper-aluminum interface, creating a stable bond with an Intermetallic Compound (IMC) layer less than 5m thick, thereby reducing contact resistance by over 60\%[4].

- Dynamic Compensation: Stress relaxation and connection loosening are major issues. New terminal systems use spring termination and dynamic compensation mechanisms that automatically adjust for thermal expansion and contraction

[5], maintaining contact force and dramatically extending the maintenance cycle.

3. The TCO Model: Strategic Value of Maintenance-Free Operation

The initial cost premium for cold-forged lugs is quickly negated by substantial long-term operational savings. In a 20-year TCO model, the maintenance-intensive nature of cast lugs is the primary driver of excess cost.

Cold-Forging: The Maintenance Killer

The dynamic compensation mechanism in advanced lugs extends the required torque verification cycle from 12 months up to 36 months. This is the maintenance killer that delivers verifiable long-term savings[6].

| Cost Type | Cold-Forged Lugs | Cast Copper Lugs | Key Financial Impact |

|---|---|---|---|

| Annual Inspection Cost | $0.7/point·year | $2.3/point year | 70\%Savings (Maintenance) |

| Fault Downtime Loss | $85/event | $480/event | 72\%Reduction in Incidents[7] |

| 20-Year TCO | $128.5/point | $196.2/textpoint | Cold-Forged is 34.5% Cheaper in the Long Run |

Strategic Conclusion and Compliance

The engineering decision is clear: the thermal risks of cast lugs are unacceptable for utility-scale BESS. The strategic choice is to prioritize cold-forged technology as the foundational component for safety and long-term profitability.

The initial investment in cold-forged technology eliminates 72\% of unexpected shutdown events and provides the only verifiable path to sustained IEC 61238 compliance and a 30% reduction in Total Cost of Ownership[8].

Always prioritize suppliers who provide independent UL 486A-B and IEC 61238 verification. Shift your focus from the initial purchasing price to long-term operational resilience and asset longevity.