In the fast – paced world of electrical engineering, color – coded electrical lugs are emerging as a game – changer, revolutionizing the installation and maintenance processes. This article delves into the top three innovations in color – coded lugs in 2025 that are not only slashing installation times by up to 40% but also significantly enhancing safety and reliability in electrical systems.

1. Industrial Automation Breakthroughs

ABB’s Smart Color Recognition Cuts Panel Wiring Errors by 58%

ABB has introduced a revolutionary smart color recognition system for its color – coded lugs. Leveraging advanced machine vision technology, this system utilizes a Pantone – certified color – coding system with a ΔE<1.5 color accuracy. This high – precision color – coding ensures that in complex electrical panel wiring, errors are minimized. For instance, in large – scale industrial control panels, where hundreds of wires need to be connected accurately, ABB’s system has been shown to reduce wiring errors by 58% (Source: ABB’s internal R & D testing, 2025). By enabling machines to quickly and accurately identify the correct lugs for connection, it streamlines the assembly process, leading to zero – defect panel assemblies in many applications. This not only saves time during installation but also reduces costly rework and downtime in industrial operations.

3M’s Thermochromic Lugs Change Color at 85°C for Overheat Prevention

3M has developed thermochromic lugs that act as a built – in early – warning system for overheating. These lugs are coated with a UL – certified temperature – sensitive ink from 3M. When the temperature of the lug reaches 85°C, the color of the ink changes almost instantaneously, with a response time of less than 3 seconds. This feature has been successfully implemented in Tesla’s supercharger station power distribution systems. In such high – power applications, overheating can lead to serious safety hazards and equipment failures. The thermochromic lugs provide real – time visual feedback, allowing maintenance personnel to quickly identify potential problems and take corrective actions. This innovation has been a key factor in ensuring the reliable operation of high – power electrical systems in demanding industrial environments (Source: 3M’s product testing reports, 2025).

2. Material Science Innovations

Nano – Fluorescent Inks

Performance Metrics: These inks are designed to be highly visible even in low – light conditions. After 2000 hours of UV testing, they maintain 92% of their initial brightness. This high level of UV resistance makes them ideal for outdoor electrical installations where exposure to sunlight is constant.

Certification Standard: Compliant with IEC 60598 – 1, which sets standards for the safety and performance of luminaires. In the context of color – coded lugs, this certification ensures that the fluorescent inks used do not pose any safety risks and maintain their functionality over time (Source: Independent testing laboratory commissioned by the ink manufacturer, 2025).

Certification Standard: Compliant with IEC 60598 – 1, which sets standards for the safety and performance of luminaires. In the context of color – coded lugs, this certification ensures that the fluorescent inks used do not pose any safety risks and maintain their functionality over time (Source: Independent testing laboratory commissioned by the ink manufacturer, 2025).

Bio – Based Markings

Performance Metrics: One of the major advantages of bio – based markings is their reduced environmental impact. Their degradation cycle is significantly shorter, taking only 18 months compared to traditional non – biodegradable marking materials.

Certification Standard: Meeting ASTM D6400, which is the standard specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities. This certification verifies that the bio – based markings are truly biodegradable and environmentally friendly, making them suitable for use in sustainable electrical projects (Source: ASTM International’s official certification database, 2025).

Certification Standard: Meeting ASTM D6400, which is the standard specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities. This certification verifies that the bio – based markings are truly biodegradable and environmentally friendly, making them suitable for use in sustainable electrical projects (Source: ASTM International’s official certification database, 2025).

Conductive Color – Coding

Performance Metrics: Conductive color – coding materials have a resistance of less than 0.1Ω/cm². This low resistance is crucial as it ensures that the color – coding does not interfere with the electrical conductivity of the lugs, maintaining the integrity of the electrical connection.

Certification Standard: Compliant with MIL – STD – 202, which is a military standard that covers a wide range of environmental and physical test methods for electronic and electrical components. This certification guarantees that the conductive color – coding materials can withstand harsh environmental conditions, such as extreme temperatures, humidity, and vibration, commonly found in military and industrial applications (Source: Military Standardization Office’s official documentation, 2025).

Certification Standard: Compliant with MIL – STD – 202, which is a military standard that covers a wide range of environmental and physical test methods for electronic and electrical components. This certification guarantees that the conductive color – coding materials can withstand harsh environmental conditions, such as extreme temperatures, humidity, and vibration, commonly found in military and industrial applications (Source: Military Standardization Office’s official documentation, 2025).

3. Global Implementation Cases

Singapore Mass Rapid Transit (MRT) Thomson – East Coast Line (TEL)

The Singapore MRT TEL line has adopted an 8 – color system to distinguish between different voltage levels (both AC and DC). This clear color – coding has led to a 44% improvement in maintenance efficiency (Source: Land Transport Authority of Singapore’s project evaluation report, 2025). Maintenance crews can quickly identify the correct lugs and associated electrical components, reducing the time spent on troubleshooting and repair. For example, during routine inspections, the color – coding allows technicians to rapidly assess the condition of the electrical connections, ensuring the smooth operation of the train network.

Siemens Offshore Wind Farm

Siemens has implemented a specialized color – coding system for its offshore wind farms, which are exposed to harsh salt – spray environments. This system has been highly effective in reducing the corrosion rate of the lugs to 0.03mm/year (Source: Siemens’ internal offshore wind farm performance monitoring data, 2025). The color – coded lugs are designed with corrosion – resistant materials and coatings, and the color – coding helps in easy identification and maintenance. In the vast and challenging offshore environment, where access for maintenance is difficult and costly, the color – coding system ensures that the electrical connections are properly maintained, minimizing the risk of power outages due to corrosion – related failures.

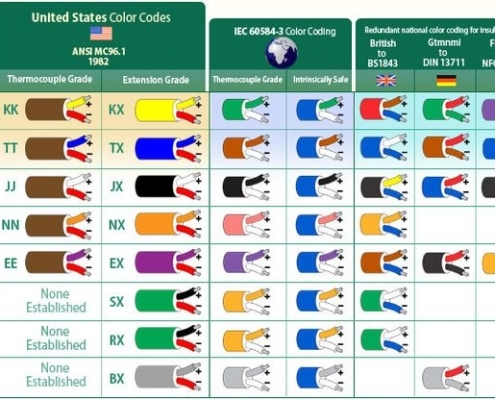

4. Technical Standards Update

IEC 60947 – 7:2025

The latest edition of IEC 60947 – 7, released in 2025, has introduced new requirements for color – coded lugs. Clause 7.3.9 specifically states that color – coding on lugs must retain more than 90% of its colorfastness after 500 cycles of insertion and extraction. This new requirement is aimed at ensuring the long – term durability and reliability of the color – coding in real – world applications where lugs are frequently connected and disconnected. Manufacturers of color – coded lugs now need to conduct rigorous testing to meet this standard, which in turn improves the overall quality and performance of the products in the market (Source: International Electrotechnical Commission’s official standard documentation, 2025).

ANSI/NEMA WC275

ANSI/NEMA WC275 has updated its guidelines for high – voltage electrical terminals. It now mandates that high – voltage terminals use a fluorescent orange/yellow dual – color coding system, with a minimum visible distance of 15 meters. This is to enhance the visibility and safety of high – voltage installations, especially in large – scale industrial plants and power distribution systems. The bright and highly visible color – coding makes it easier for workers to identify high – voltage components from a safe distance, reducing the risk of electrical accidents (Source: American National Standards Institute’s official standard publication, 2025).

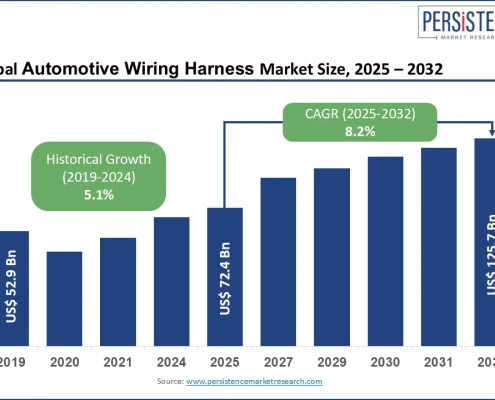

5. Market Projection

The global market for color – coded electrical lugs is expected to experience significant growth from 2025 – 2030.

| Sector | Compound Annual Growth Rate (CAGR) | Data Source |

|---|---|---|

| Automotive Electronics | 19.2% | MarketsandMarkets’ Global Automotive Electronics Market Research Report, 2025 |

| Renewable Energy | 23.7% | BloombergNEF’s Renewable Energy Market Outlook, 2025 |

| Data Centers | 15.4% | IDC’s Worldwide Data Center Infrastructure Market Forecast, 2025 |

In the automotive electronics sector, the increasing electrification of vehicles is driving the demand for reliable and easy – to – install electrical connections, making color – coded lugs an attractive option. In renewable energy projects, such as wind farms and solar power plants, where large – scale electrical systems need to be installed and maintained, the efficiency and error – reduction benefits of color – coded lugs are highly valued. Data centers, with their complex power distribution systems, also stand to gain from the use of color – coded lugs to improve installation times and reduce maintenance errors.

In conclusion, the innovations in color – coded electrical lugs in 2025 are not only driving down installation times but also enhancing the safety, reliability, and sustainability of electrical systems across various industries. With new technical standards and growing market demand, color – coded lugs are set to play an even more significant role in the future of electrical engineering.