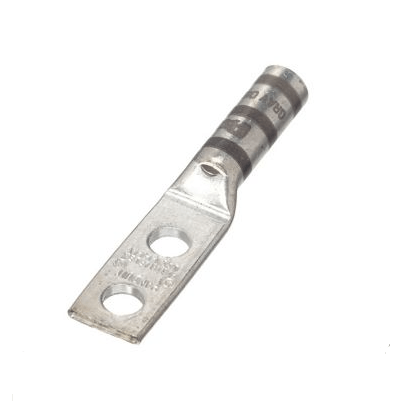

Compression Lug Color Codes: A Data-Driven Comparison of Panduit, ABB & Industry Standards

For electrical professionals, selecting the correct compression lug is a critical decision that impacts safety, performance, and compliance. The industry’s color-coding system is designed to simplify this choice, but a dangerous assumption persists: that a red lug from one manufacturer is identical to a red lug from another.

Through a detailed analysis of official manufacturer specifications, this guide cuts through the confusion. We provide a professional comparison of Panduit, ABB (Thomas & Betts), and other major brands, highlighting the critical similarities and differences you need to know to avoid costly errors and ensure reliable, code-compliant terminations every time.

The Golden Rule of Color Codes

Treat color as a universal guide, not an absolute truth. The final authority for any compression lug is always the manufacturer’s official specification sheet and the ** markings stamped on the lug’s barrel.** Relying solely on color is a significant professional risk.

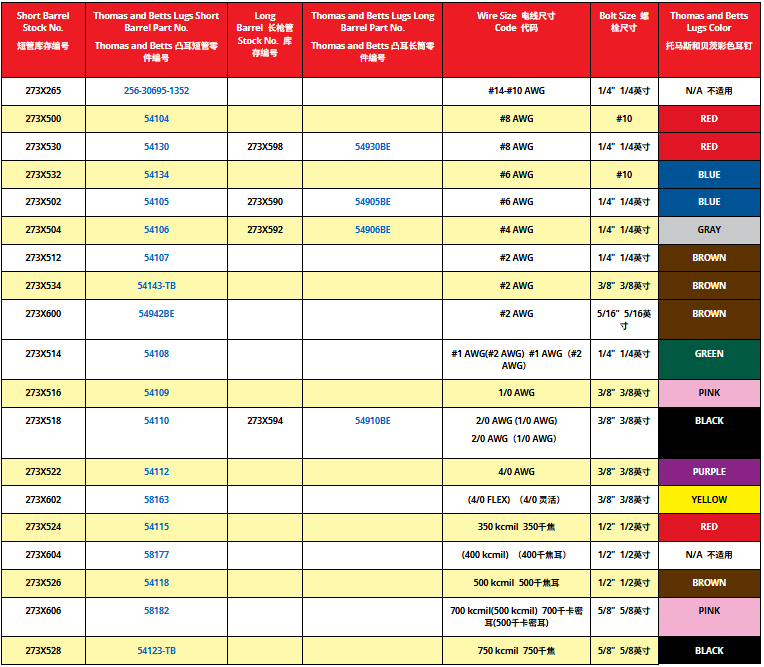

Manufacturer Comparison: Panduit vs. ABB (Thomas & Betts)

Based on an analysis of official resources, including the ABB (Thomas & Betts) Compression Connectors for Copper Conductors PDF catalogue and product data from authorized distributors like Specialized.net, we can draw clear comparisons.

Core Color Code Alignment (AWG #14 – #0)

For the most common wire sizes, Panduit’s PCID series and ABB’s T&B TLC series are perfectly aligned. This interoperability is by design.

| Lug Color | Panduit PCID Series (AWG) | ABB T&B TLC Series (AWG) | Metric Range (mm²) |

|---|---|---|---|

| Blue | #14 – #12 | #14 – #12 | 2.5 – 4 mm² |

| Yellow | #10 – #8 | #10 – #8 | 6 – 10 mm² |

| Red | #6 – #4 | #6 – #4 | 16 – 25 mm² |

| Black | #2 – #0 | #2 – #0 | 35 – 50 mm² |

*Table 1: High-consistency color code range for common wire sizes.*

Critical Difference: Large Wire Sizes (> #0 AWG)

This is where the most important divergence occurs, creating a potential point of failure.

ABB (Thomas & Betts):

The ABB standard, as detailed in their catalogue, explicitly uses a Grey compression lug for the 4/0 AWG (0000) to 250 kcmil wire range.Panduit:

Grey is not a standard color in Panduit’s PCID color-code system for large copper lugs. For sizes like 250 kcmil, Panduit relies on:Clear barrel stampings (e.g., “250”).

Distinct product numbering (e.g., PCID-250).

Often, the lug may remain a bare copper finish.

The Risk: A professional trained on the ABB system might see a grey lug from another supplier and assume it is for 250 kcmil, potentially leading to a catastrophic misapplication if that supplier uses grey for a different purpose.

Beyond Panduit and ABB: The Wider Industry Landscape

To make truly informed decisions, it’s essential to understand how other major players approach the market.

Burndy (a Hubbell company): A giant in the industry, Burndy’s HYCOL series color-coding is largely identical to the Panduit/ABB standard for common sizes (Blue, Yellow, Red, Black). However, for larger sizes, they may use different colors or identifiers. Always consult a Burndy HYCOL catalogue for verification.

ILSCO: Another leading manufacturer, ILSCO’s CU-BC series also adheres to the same core color scheme for simplicity. However, their product lines for aluminum conductors or specialized applications may have unique coding.

Nelson (a nVent company): Nelson’s compression lug offerings also follow the industry-standard color pattern for common sizes, but again, specifics for large or unique lugs must be verified.

Key Insight: The consistency across Panduit, ABB, Burndy, ILSCO, and Nelson for sizes #14 – #0 AWG is a strong industry norm. This makes the large wire size divergence between ABB and Panduit a particularly critical exception to remember.

The 4-Step Professional Selection Process

Identify: Determine the exact conductor size (AWG/kcmil) and material (Cu/Al).

Match (Color): Use the color code as a preliminary visual filter.

Verify (Specs): This is the non-negotiable step. Cross-reference the color against the stamped markings on the lug and the official manufacturer datasheet.

Validate (System): Ensure you have the correct, manufacturer-specified crimping die and tool. A Panduit lug requires a Panduit die for a UL-compliant, guaranteed crimp. Using an ABB die on a Panduit lug (even if it “fits”) voids warranties and compromises the connection’s integrity.

Frequently Asked Questions (FAQs)

I only have ABB dies. Can I crimp a Panduit lug?

It is not recommended and may void warranties and listings. While the lugs may be dimensionally similar, the tooling systems are engineered as matched pairs. The specific geometry of the die and the indentation it forms is designed to work with the lug’s metallurgy and wall thickness to create a known, reliable gas-tight connection. Using a mismatched die risks an under-crimped or over-crimped connection, which can overheat and fail. For guaranteed performance and safety, always use the tooling specified by the lug manufacturer.

Conclusion: Precision Engineering Demands Precision Selection

In electrical termination, professionalism is defined by a commitment to precision over assumption. The high degree of alignment between Panduit, ABB, and other leaders is helpful, but the critical differences—like ABB’s use of Grey for large sizes—highlight the absolute necessity of verifying against official specifications.

Protect your work, your reputation, and your safety by making a habit of:

Using color as a guide.

Confirming with barrel stamps and official catalogues.

Using manufacturer-matched tooling systems.

This disciplined approach ensures every connection you make is not just good, but guaranteed to be perfect.

Resources & Further Reading:

Official Specifications: Always confirm against the ABB (T&B) Compression Connectors Catalogue and Panduit’s Official Resources.