Copper vs. Aluminum: Choosing the Right Crimp Terminals for Industrial Applications

The Big Picture

Choosing between a copper and an aluminum crimp terminal is more than just a material decision—it’s a critical engineering and financial choice. While copper is the undisputed champion for high-reliability, mission-critical applications due to its superior conductivity, strength, and corrosion resistance, aluminum provides a cost-effective, lightweight alternative ideal for large-scale, long-distance projects. The key to a successful project lies not in choosing one over the other, but in understanding the specific demands of your application and adhering to meticulous installation standards.

1. Introduction: The Strategic Decision Behind Every Connection

In the demanding world of heavy industry, a single failed electrical connection can trigger a chain reaction of costly consequences, from equipment damage and expensive downtime to serious safety hazards. That’s why selecting the right electrical terminal requires a comprehensive approach that considers not just the initial purchase price, but the total cost of ownership (TCO) over the entire lifecycle of the project 1, 2.

Table 1: Copper vs. Aluminum Crimp Terminals at a Glance

| Feature | Copper | Aluminum | In-depth Analysis |

| Conductivity | Excellent 3, 4 | Good 5 | Copper’s conductivity is second only to silver 6. For the same cross-section, copper’s current-carrying capacity is approximately 30% higher than aluminum 4. |

| Resistivity | Approx. 4 | Approx. 4 | Copper’s resistivity is roughly 1.68 times lower than aluminum 4, which means less energy loss and heat generation. |

| Tensile Strength | Much higher than aluminum 3, 7 | Lower than copper 3, 5, 7 | Copper’s tensile strength is about 40% better than aluminum 3, making it more durable in installation and high-stress environments. |

| Thermal Expansion | /℃ 8 | /℃ 8 | Aluminum’s thermal expansion coefficient is 35% higher than copper 8, which can lead to loose connections and creep during thermal cycling. |

| Density | Approx. 5 | Approx. 5 | Aluminum is significantly lighter than copper 5, providing a major weight advantage in long-distance and weight-sensitive applications 3. |

| Oxide Properties | Conductive 5, 7 | Insulating 5, 7 | Copper’s oxide layer is conductive, ensuring long-term electrical stability 7. Aluminum’s oxide layer is insulating, which increases contact resistance and heat 5, 7. |

| Cost | Higher 3, 5 | Significantly lower 1, 3, 5 | Aluminum is about half the price of copper 3, leading to substantial cost savings on large-scale projects 5. |

2. The Case for Copper: Performance and Unwavering Reliability

Copper is the gold standard for electrical conductors for a reason. Its conductivity is second only to silver 6, and with a resistivity about 1.68 times lower than aluminum 4, it allows a cable of the same size to carry approximately 30% more current. This efficiency directly reduces energy loss and minimizes heat generation, a critical factor for safety and system longevity.

Beyond its electrical prowess, copper is inherently durable. Its tensile strength is about 40% higher than aluminum 3, making it less susceptible to breakage during installation and more resistant to vibration and mechanical stress over time 1, 3, 7.

A key advantage is its natural corrosion resistance. When copper oxidizes, it forms a soft, conductive layer that doesn’t impede electrical flow 5, 7. This makes it a reliable choice for long-term stability, particularly in wet or harsh chemical environments.

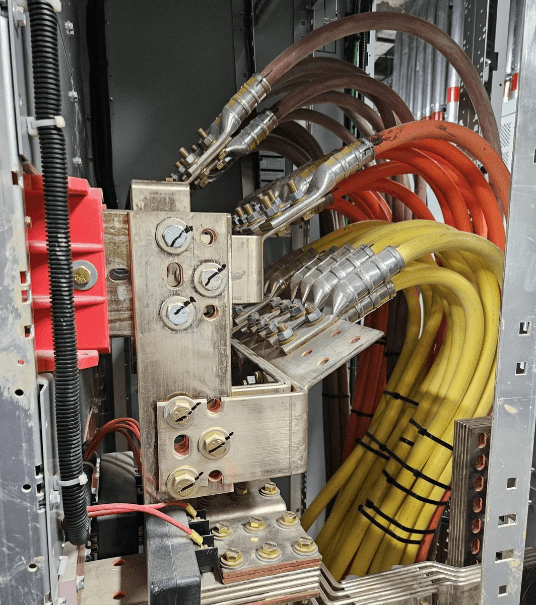

Copper is the material of choice for mission-critical applications like data centers and EV charging stations, where power demands are high and failure is not an option 4. A study of a Microsoft data center found it contained a staggering 2,177 tons of copper 9, underscoring its role as the backbone of modern, high-density power infrastructure.

3. The Case for Aluminum: Strategic Cost and Weight Savings

Aluminum’s value proposition is simple: it’s significantly lighter and more affordable than copper, at about half the price 3, 5. For massive projects like solar farms or utility transmission lines, these savings on materials and labor can be a game-changer 10.

However, aluminum presents two primary challenges:

- Oxidation: Aluminum quickly forms a hard, insulating oxide layer when exposed to air, which can increase contact resistance and lead to dangerous overheating if not managed properly 5, 7.

- Thermal Expansion: Its thermal expansion coefficient is 35% higher than copper 8. This can cause connections to loosen over time with repeated heating and cooling cycles.

To mitigate these risks, a systematic installation process is non-negotiable. This includes using specialized anti-oxidant compounds 11, 12, 13 and dual-rated connectors 14, 15. Failing to use the right tools and techniques can negate any upfront cost savings and lead to long-term reliability issues 10, 16.

4. The Cornerstone of Success: Standards and Installation

No matter the material, a crimp terminal‘s strength is only as good as its weakest link—the crimp itself 17. The crimping process is a “cold forging” method that physically molds the wire and terminal into a single, conductive mass.

The integrity of this connection hinges on using the correct tool and die set 18, 16. An improper crimp—too loose or too tight—can introduce air gaps, damage wire strands, and lead to high resistance and failure 17.

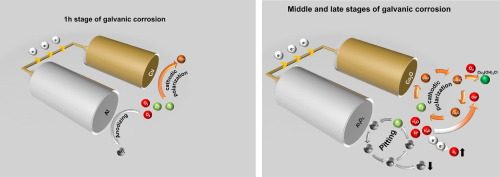

You must also consider galvanic corrosion, which occurs when dissimilar metals like aluminum and copper are in electrical contact in the presence of an electrolyte 19, 20. This electrochemical reaction can cause rapid degradation of the more “active” metal (aluminum). This is why specialized bi-metallic connectors are essential—they act as a robust barrier to prevent direct contact and ensure the connection’s longevity 19.

Table 2: Crimp Terminal Selection Matrix by Application

| Application | Recommended Material | Primary Drivers | Key Engineering Considerations |

| Data Centers | Copper | High reliability, high current density | Thermal management, zero failure rate, low resistivity 9 |

| Solar Farms | Aluminum, Bi-metallic | Cost and weight optimization, long cable runs | Connection integrity under thermal expansion, anti-oxidation, TCO 10, 15 |

| EV Charging Stations | Copper | High current, durability, safety | Heat generation at high currents, tensile strength 4 |

| Overhead Power Lines | Aluminum | Lightweight, cost savings | Tensile strength, sag mitigation with temperature changes 8 |

| Harsh/Marine Environments | Copper, Tin-plated Copper | Corrosion resistance, long-term stability | Oxide properties, moisture/chemical protection 1, 7 |

5. Conclusion: A Final Framework for Decision-Making

The choice between copper and aluminum is not a question of which is better, but which is best for your specific needs.

- For high-reliability projects, choose copper. The initial cost is an investment in superior safety, performance, and a lower TCO through minimal maintenance.

- For large-scale, cost-sensitive projects, aluminum is a powerful alternative. However, it requires an unwavering commitment to engineering-backed installation practices. Failure to use the correct tools, dies, and antioxidant compounds will undermine any cost savings and introduce significant long-term risks.

A successful project is built on the foundation of the right material, meticulous installation, and a deep understanding of industry standards.