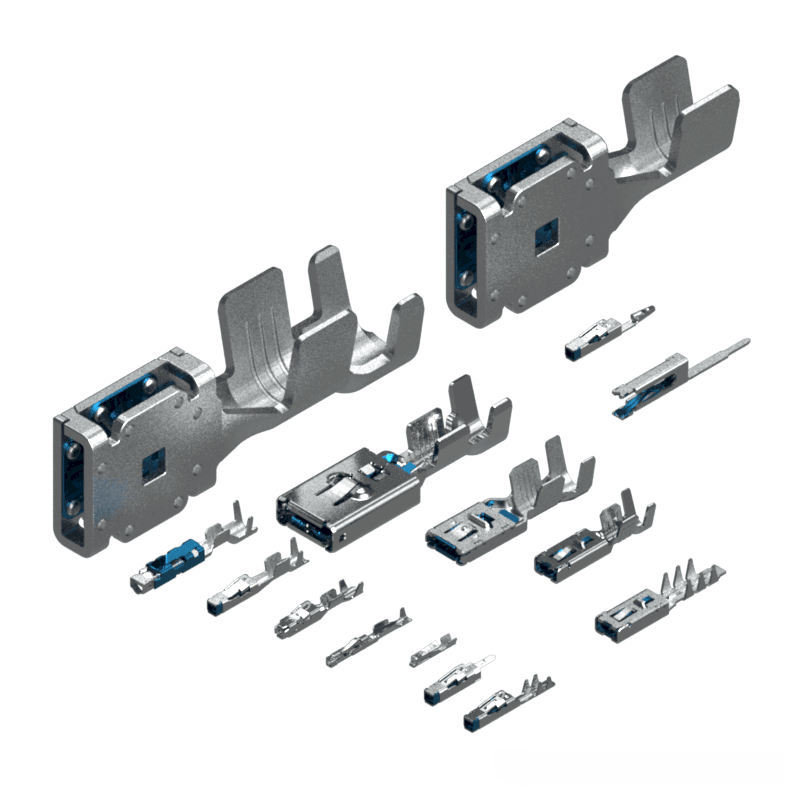

Pin terminal is a common wire connector, usually used in low-voltage circuits, this terminal is usually composed of two parts: pins and sockets, pins are made of metal materials, usually has a curved shape, in order to insert the socket, the socket usually has an opening, can accept the pins and will be fastened in the terminal inside the lug. This kind of terminal is simple and convenient to install, high reliability, widely used in a variety of electronic equipment, instrumentation, automatic control systems and other fields.

How to use pin terminal blocks

1, pay attention to the specifications and models of the terminals, select the appropriate model and specifications of the pin type terminals to ensure that it can meet the wiring requirements, at the same time, should be considered in accordance with the actual situation of the material and quality of the terminals, as far as possible to choose a product with excellent durability.

2, clean terminals, the line to be wired for pre-treatment, including the removal of external dirt and impurities, so that the wire necessary to clean and smooth.

3, prepare wiring tools, prepare a strategic tip cutter and a timely sorter, and placed in a convenient location, use strategic tip cutter to cut off the jacket and insulator, so that the wire to the appropriate length into the terminal, use timely sorter to separate a variety of different colors and models of wire.

4, with a strategic tip shear knife will be hindered in the desired length of the wire, and then insert the wire into the pin type terminals to ensure good contact, do not insert the wire is too deep or too shallow, especially in the insertion of the wire, leaving the wire at the end of the roughly do not exceed the insertion of the mouth of the 1 / 8.

5, inserted wires, use timely sorter again to confirm that a variety of different colors and models of wires have been separated, and then inside the hard squeeze, so that the wires are firmly locked in the terminal, to ensure good contact with the terminals.

6, after the completion of the inspection work, to ensure that the wiring is correct, there is no power outage or power loss, to ensure that the pin type terminals solid and firm, not because of a little shaken and caused by power outage or power loss. In the use of pin type terminals, should be based on the actual situation to choose the appropriate terminal type and specifications, need to pay attention to safety, for the correct wiring, after the completion of the work to check whether the work is correct as well as the stability of the equipment to carry out quality checks.

Usage of pin type terminal block

1, electrical box internal connection

Pin type terminals can be used for electrical box between different locations within the circuit connection, in the electrical box, they are usually used to connect the controller, sensors and other equipment.

2、Lighting system

Pin type terminals can also be used for lighting system installation, for example, when the circuit needs to be connected to multiple lamps, pin type terminals can make the connection more convenient and easy to manage, can reduce the failure rate and maintenance costs.

3、Battery system

Pin type terminals can be used for battery system connection, such as solar and wind energy systems in the battery and inverter connection between the pin type terminals can provide high power and reliability, but also can reduce the voltage loss in the circuit.

4, automation system

Pin type terminals are widely used in automation systems, such as PLC and other field bus systems in the connection, pin type terminals can be quickly wired and very reliable to maintain complex control requirements.

5、Laboratory equipment

Pin type terminals can also be used in laboratory equipment, such as electronic test equipment and circuit boards, they can provide reliable electrical connections and quickly change the connection to adapt to different experimental requirements.