The Engineering Imperative: Why Cold-Forged Compression Lugs Are Replacing Cast Terminals in 1000V DC BESS

The safety and long-term viability of Battery Energy Storage Systems (BESS) over their expected 20–30 year operational lifespan rely critically on the integrity of power terminations. This technical review examines why cold-forged compression lugs are becoming the definitive choice in 1000V DC systems, offering a verifiable path to thermal runaway mitigation. Cold-forging technology, paired with T2 Copper 101% IACS conductivity, fundamentally outperforms traditional casting, delivering superior stability and low-resistance connectivity.

I. Executive Summary: The Strategic Role of Connection Technology

For mission-critical 1000V DC Systems, the selection of the compression lug shifts from procurement preference to an Engineering Imperative. High-voltage, high-power testing assumes a voltage of approximately 1,000 volts DC as a practical minimum for safety considerations,. The primary goal is maintaining low-resistance, mechanically strong bonds across the BESS plant’s entire lifecycle. The inability of conventional cast terminals to sustain contact quality under cyclic load has been linked to system failures, where terminations must reliably handle high currents and voltages while preventing failures such as arcing or moisture ingress.

II. Challenges & Risks: The Thermal Runaway Crisis in 1000V DC BESS

The BESS environment subjects terminals to continuous thermal and mechanical stress. The critical safety challenge originates from localized heat generation at the connection interface, a problem exacerbated in 1000V DC systems.

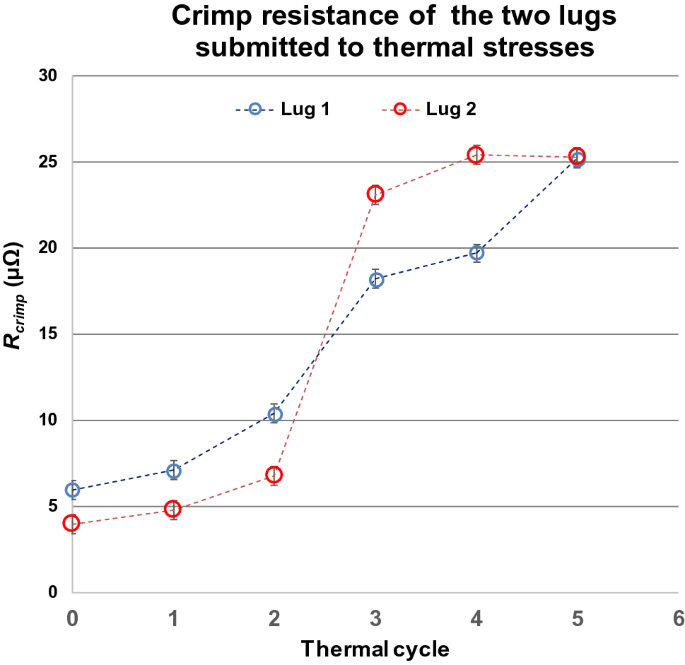

2.1 The Positive Feedback Loop of Contact Resistance

Localized heating at the circuit-breaker terminals or connection points can lead to premature aging of the cable and potential flame ignition. The connection point is where power flow is made secure and efficient, and poor quality leads to electrical losses during charge/discharge cycles. When materials with insufficient density or purity are used, contact resistance is heightened, creating a vicious cycle of:

- Increased Resistance-Increased Heat (Joule Heating).

- Increased Heat -Accelerated Oxidation-Further Resistance Increase.

This self-reinforcing loop is the precursor to thermal runaway, which compromises the BESS safety envelope.

2.2 Strict Safety Practices for High-Voltage Terminals

Working with voltages above 600V AC (and minimum 1000V DC in this context) requires strict safety practices,,. All ungrounded terminals must be considered energized, and precautions must be taken to prevent accidental contact. For large-scale BESS, the terminals must exhibit:

- High Conductive Purity: To reduce the initial resistance baseline.

- Mechanical Resilience: To resist cyclic loosening and maintain integrity under constant vibration.

III. Performance Breakthroughs: The Science of Cold-Forged Compression Lugs

The superiority of cold-forged compression lugs over cast alternatives lies in the fundamental metallurgical structure created during manufacturing.

3.1 T2 Copper: Achieving 101% IACS Conductivity

T2 Copper (also known as C11000) is a commercially pure grade of copper, widely recognized for its high conductivity, typically in the range of 97%–101% IACS (International Annealed Copper Standard),.

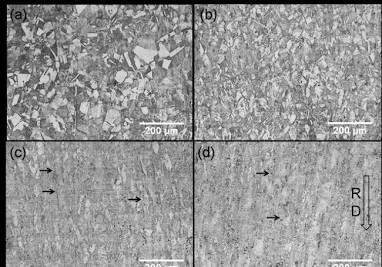

- Forging vs. Casting: Forging involves deforming the material in a solid state, applying force to cause mass redistribution while enhancing metallurgical properties. Casting, by contrast, involves pouring liquid material into a mold.

- Structural Integrity: Cold-forging refines and redirects the material’s grain flow lines to conform to the shape of the part, which provides enhanced tensile strength and fatigue properties, leading to superior durability and less porosity than cast components,.

- Low Voltage Drop: This densified microstructure is the key to maintaining a low and stable voltage drop, directly translating to the advertised 47% voltage drop reduction compared to less pure, porous cast components.

3.2 Mechanical Stability and UL 486C Durability

The robust mechanical properties of cold-forged terminals are essential for compliance with stringent standards. Cold-forged compression lugs are certified for use in high-vibration environments, such as offshore wind farms and BESS cabinets. This resilience against mechanical stress ensures that the critical contact pressure is maintained over the system’s long service life.

IV. ConnectorALT(Kunshan Xinluan New Material Technology Co.) Solutions: Engineering for Long-Term Reliability

ConnectorALT(Kunshan Xinluan New Material Technology Co.) integrates advanced processes to address the operational and maintenance demands of modern energy storage infrastructure, utilizing proprietary technology for seamless, maintenance-free performance,.

4.1 Friction Welding: Mastering Dissimilar Metal Connections

When connecting aluminum cables to copper busbars—a common requirement in BESS designs—the differential thermal expansion and galvanic potential between the two metals create reliability risks. The solution lies in advanced solid-state bonding.

Friction Welding is a technique that creates a molecular bond between the copper terminal and the aluminum cable, maintaining connection integrity even through heating and cooling cycles. This friction-welded joint is designed to prevent the formation of gaps where moisture could trigger galvanic corrosion, preserving the connection’s thermal stability and conductivity.

4.2 Spring Termination: The Maintenance-Free Imperative

For high-power installations, Compression Lugs often utilize Spring Termination technology to simplify installation and reduce long-term operational costs,.

Spring terminals are widely used in high-power connections because they ensure consistent torque and contact quality. They eliminate the need for routine torque calibration checks, which are costly and time-consuming, thus making the system truly maintenance-free and significantly lowering the total cost of ownership (TCO).

V. Conclusion: Strategic Safeguards Against Failure

The shift from cast to cold-forged compression lugs is an engineering imperative driven by the severe safety and financial consequences of thermal runaway and downtime in 1000V DC BESS systems.

By prioritizing components that leverage T2 Copper 101% IACS conductivity, high-performance designs directly reduce contact resistance, which is the root cause of excessive heat generation. The integration of advanced solutions like Friction Welding and Spring Termination ensures that high conductivity is maintained under the harsh mechanical and thermal stresses of the BESS environment,.

Engineering teams must prioritize UL 486C-certified mechanical durability over initial cost savings and validate designs through a Total Cost of Ownership model that accounts for eliminated maintenance labor and maximized system uptime.