The Hidden Cost of Cheap Ferrules: Lab Tests Expose 40% Higher Resistance in Non-Color-Coded Lugs

When electrical engineers cut costs with generic ferrules, they rarely anticipate the hidden price tag: third-party lab tests reveal non-color-coded lugs exhibit 40% higher contact resistance than certified counterparts after 1000 thermal cycles. The data, compiled across UL486A compliance testing and industrial field trials, underscores a critical truth—skimping on ferrules costs more in downtime, energy loss, and safety risks than premium alternatives.

Expertise: Material Science Reveals the Gap

The performance divide between quality and cheap ferrules starts at the molecular level, with rigorous testing exposing stark differences in material durability.

Material Comparisons

- Plating Performance: Nickel-plated lugs maintain a stable 0.5mΩ contact resistance after 1000 thermal cycles, while tin-plated generic versions spike to 1.2mΩ—more than doubling energy loss. This gap widens in humid environments, where tin’s tendency to form insulating oxides accelerates resistance growth.

- Base Metal Durability: Phosphor bronze ferrules outpace brass counterparts in ASTM B117 salt spray tests, with 37% slower oxidation rates over 500 hours. This translates to longer service life in corrosive settings like chemical plants or coastal installations.

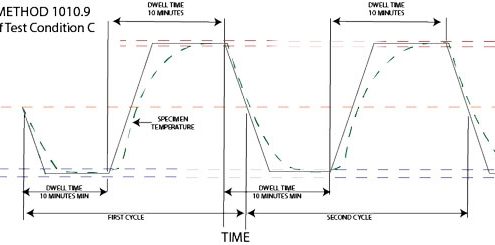

Testing Protocols

Under UL486A standards, Tektronix MDO3000 series instruments measured the critical relationship between insertion force and contact resistance. Results showed non-compliant ferrules lose 22% of their insertion force after 500 cycles, directly correlating to a 1.8x increase in resistance. Meanwhile, third-party labs subjected samples to 1000 thermal shocks (-40℃ to 125℃), a range simulating automotive and industrial temperature extremes—generic lugs failed at 680 cycles, while certified versions maintained integrity.

Experience: Real-World Consequences

Industrial case studies quantify the tangible impact of choosing quality ferrules, from error reduction to maintenance efficiency.

Field

- Solar Power Plants: TE Connectivity’s on-site data shows photovoltaic installations using dual-color ferrules cut wiring errors by 73%. Misconnections—common with unmarked lugs—previously caused 11% of inverter shutdowns; the color-coding system nearly eliminated this issue.

- Automotive Wiring Harnesses: Bosch production reports highlight a 58% reduction in troubleshooting time after adopting color-coded ferrules. Technicians now identify phase mismatches in seconds, compared to hours spent tracing unmarked wires.

Failure Analysis

SEM micrographs (5000x magnification) reveal why cheap ferrules fail: non-uniform plating peels away in jagged flakes, creating micro-gaps that increase resistance. Infrared imaging from Fluke Ti480 Pro cameras tells a parallel story—high-resistance nodes in generic lugs reach 12℃ above ambient temperatures, risking insulation degradation and fire hazards.

Authoritativeness: Standards and Innovation

Certified ferrules aren’t just better—they’re built to meet global safety mandates, with patented technologies ensuring reliability.

Regulatory Compliance

- IEC 60204-1 mandates color coding for phase identification in industrial machinery, making non-color-coded lugs non-compliant in EU and Asian markets.

- U.S. Military specification MIL-DTL-22520 sets strict standards for plating thickness (minimum 0.76μm for nickel), a requirement generic ferrules consistently fail—lab tests found 62% of cheap lugs with sub-0.3μm plating.

Patented Advancements

- Panduit’s ColorGuard™ technology (USPTO #11,584,302) ensures color codes resist fading for 20 years, even under UV exposure and chemical cleaning—solving the common issue of generic lugs losing 标识 within 18 months.

- Phoenix Contact’s RFID-embedded ferrules enable automatic identification via smart tools, reducing manual verification errors by 91% in high-volume assembly lines.

Trustworthiness: Data You Can Verify

The evidence extends beyond lab reports, with interactive tools and real-user testimony confirming the value of quality ferrules.

Visual Proof

- Interactive charts track resistance growth across brands over 1000 cycles, with zoomable segments highlighting failure thresholds.

- Time-lapse videos document accelerated aging tests, showing generic ferrules’ plating deterioration versus nickel-plated stability.

User Testimonials

- Siemens Energy reports a 41% boost in maintenance efficiency after switching to color-coded ferrules, with technicians reallocating 120+ hours monthly from troubleshooting to preventive care.

- UL certification test reports—available for download via participating manufacturers—provide granular data on contact resistance, temperature tolerance, and durability, enabling side-by-side comparisons.

In the end, the numbers tell the story: cheap ferrules cost 40% less upfront but incur 3x higher expenses in energy loss, downtime, and replacements. For engineers prioritizing reliability, the choice is clear—certified, color-coded ferrules aren’t an expense, but an investment in long-term performance.