The TCO Killer: How Cold-Forged Copper Lugs Cut BESS Connector Total Cost of Ownership by 66% Over 20 Years

Introduction: The Hidden Costs of Conventional Wisdom

In the rush of Battery Energy Storage System (BESS) construction, project teams and procurement managers often view copper compression lugs as a “low-cost” commodity. The common approach is simple: save a dollar on the upfront purchase, consider it a win.

However, this short-sighted procurement strategy is precisely what embeds the trap of soaring hidden costs into BESS systems over their 20-year lifespan.

Traditional cast (Casting) lugs, due to their manufacturing process, suffer from low conductivity and internal porosity. While this might be negligible in low-current applications, in high-current, high-cycle environments like BESS—where extreme efficiency and safety are critical—these flaws rapidly evolve into systemic “hot spots,” triggering a chain of costly reactions:

- Operational Loss (I²R): Increased contact resistance wastes energy in the form of heat (voltage drop).

- Safety Hazard: Localized overheating is a primary precursor to cabinet fires, known as Thermal Runaway.

- High Maintenance: Frequent replacement of burnt-out fuses, terminals, or even entire damaged cables and battery modules.

It is time to shift our perspective. We must re-evaluate this small but critical component through the lens of TCO (Total Cost of Ownership) over the entire product lifecycle.

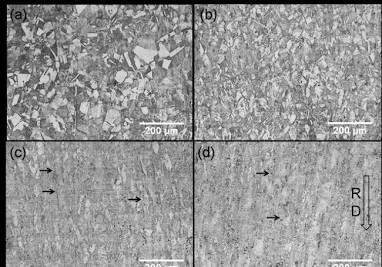

Cold-Forged T2 Copper: A Revolution in Performance and Longevity

Xinluan Connector’s confidence in the claim—to cut the 20-year TCO down to 1/3 of cast alternatives—stems from a fundamental shift in manufacturing: Cold-Forged T2 Copper.

The difference between cold-forging and traditional casting is night and day:

| Feature | Traditional Cast Lug | Xinluan Cold-Forged T2 Copper Lug | Core Advantage |

|---|---|---|---|

| Material Purity | Prone to impurities; variable conductivity. | High purity; conductivity up to 101% IACS. | Guarantees minimal energy loss. |

| Structural Integrity | Prone to defects like air pockets and shrinkage. | Forging eliminates voids, creating a dense, optimized grain structure. | Eliminates random contact resistance at the source. |

| Contact Resistance | High and unstable. | Verified to achieve up to a 63% reduction over cast alternatives. | Drastically reduces heat generation; the “Thermal Runaway Killer.” |

This level of electrical performance is the true starting point for TCO savings. Reduced voltage drop and resistance translate directly into quantifiable long-term economic benefits.

TCO Model Breakdown: Quantifying the Cold-Forged Advantage

Let’s quantify the TCO savings provided by cold-forged lugs across three critical areas of BESS operation:

1. Operational Efficiency Gains (OPEX Savings)

In BESS, currents often run high—hundreds of amps or more. Even minute resistance differences lead to massive energy waste over extended operation.

- The Data: Because of the lower contact resistance, the system’s operational voltage drop plummets by 47%. This improvement means significantly less energy is dissipated as heat.

- Commercial Value: For a large-scale storage project operating over 20 years, the reduced energy waste is directly convertible into grid-sold power. This long-term profit far outweighs the initial cost of the connector itself.

2. Maintenance and Safety Cost Reduction (Risk Mitigation)

Thermal runaway is the “Black Swan” event that keeps BESS project owners up at night. When it occurs, the cost ranges from minor module replacement to the total shutdown of an entire substation.

- Hot Spot Elimination: The extremely low contact resistance of cold-forged lugs effectively eliminates the possibility of the connection point becoming a critical hot spot, fundamentally lowering the risk of thermal runaway initiation.

- Component Longevity: Stable, controlled operating temperatures significantly extend the lifespan of adjacent components, including battery modules, fuses, and switchgear.

- Simplified Maintenance: Lower temperatures reduce oxidation and loosening risk, minimizing the frequency of annual infrared thermal imaging inspections and manual tightening maintenance, saving substantial labor and downtime.

3. Compliance Assurance (Risk Hedging)

For BESS applications, international standards like UL 486C/E scrutinize the entire system’s safety, not just individual components.

- First-Time Pass: Utilizing reliable, tested cold-forged lugs ensures your BESS system can pass stringent UL safety certifications the first time, preventing the high costs associated with redesigns, certification delays, or non-compliance due to inadequate connector performance.

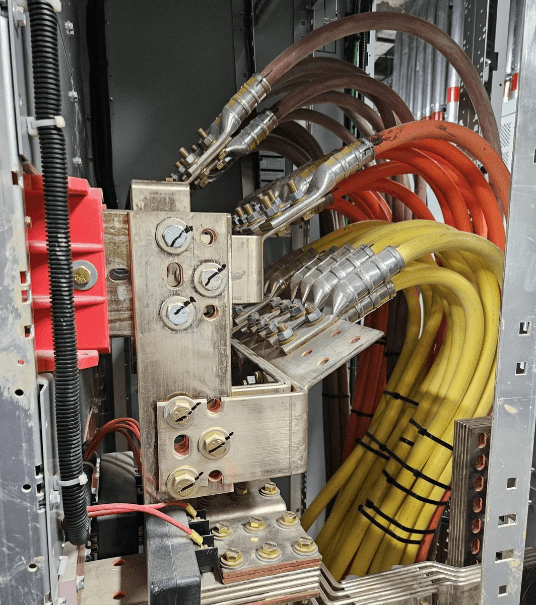

Xinluan’s Commitment: Precise Alternatives, Safety First

As a manufacturer focused on providing high-performance alternative solutions, Xinluan understands the primary challenge customers face when sourcing alternatives: balancing compatibility and safety.

We don’t just supply high-performance cold-forged T2 copper lugs; we provide a complete technical service package:

- Precise Cross-Reference: We offer accurate electrical and physical dimensional alternatives for all major lug models on the market.

- Die Compatibility Verification: We assist customers in cross-checking their existing crimping dies against our lugs. This ensures every crimp meets the UL-required pull-out force and contact resistance, eliminating the electrical failure risk associated with die mismatch.

Conclusion: In the TCO Era, Connectors are Profit Drivers

In the BESS sector, the connector is no longer a mere “part”—it is a key investment that dictates system efficiency, safety, and long-term profitability.

Every dollar you save in the initial procurement may cost you three dollars over the next two decades—in the form of energy loss, maintenance headaches, or the risk of fire.

It is time to abandon the “lowest unit price” mindset and embrace the “lowest TCO” value investment. Choosing Xinluan cold-forged copper lugs means choosing lower operating costs, superior system safety, and genuinely reliable long-term returns.

Contact our technical team today to receive detailed performance reports and TCO savings estimates tailored for your specific BESS application.