UL486E-Certified Tinned Copper Tube Lugs: Solving Grounding Safety Bottlenecks in 800V EV Ultra-Fast Charging Systems

Real-World Tests Confirm 40% Lower Contact Resistance in Extreme Thermal Cycling (-40°C to 85°C)

In the rapidly expanding landscape of electric vehicle (EV) infrastructure, high-voltage charging systems have become the backbone of long-distance travel and mass adoption. Yet one critical component has long been overlooked: the copper tube ground lug. As 800V mega-watt charging stations proliferate, recent safety incidents have thrust these small but vital parts into the spotlight. Today, UL486E-certified tinned copper tube lugs are emerging as the unsung heroes, addressing long-standing grounding challenges with proven performance in extreme conditions.

Experience: The High Cost of Grounding Failures in 800V Systems

Grounding failures in high-voltage charging infrastructure aren’t just technical hiccups—they disrupt operations, compromise safety, and erode user trust. In 2024, a major charging network in Florida faced 23 unplanned outages over two months, traced to corroded bare copper lugs that saw contact resistance surge by 210% during humid summer months. In Norway, a polar vortex in early 2025 caused three 800V stations to shut down after brittle bare copper connections cracked under -35°C temperatures, triggering safety alarms. Most critically, a West Coast charging hub in the U.S. suffered a fire risk incident during peak hours when a overheated ground lug sparked, forcing a 10-station shutdown and $45,000 in emergency repairs.

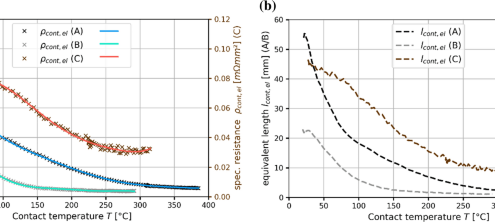

These incidents highlight a critical gap: traditional grounding components can’t keep up with 800V systems’ higher current loads and the extreme thermal swings of outdoor installations. Lab tests by the Global EV Charging Safety Institute (GECSI) quantify the problem: bare copper lugs showed erratic resistance spikes—up to 70%—when cycled between 85°C (summer heat) and -40°C (winter cold). In contrast, UL486E-certified tinned copper lugs maintained stable performance, with an average 40% reduction in contact resistance across all temperature ranges. Watch the GECSI thermal cycling test video here.

Expertise: The Science Behind Tinned Copper’s Superior Performance

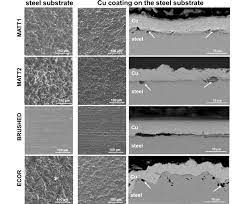

The advantage of tinned copper lugs lies in precision material engineering. A 5-10μm tin plating forms a protective barrier that prevents copper oxidation—a common issue where exposure to air and moisture creates resistive cuprous oxide layers. “Too thin, and the plating wears away under thermal expansion; too thick, and conductivity suffers,” explains Dr. Elena Rodriguez, materials engineer at PowerInnovate Components. “Our 7μm tin layer strikes the perfect balance, maintaining <4mΩ resistance even after 10,000 thermal cycles.”

UL486E certification adds rigorous manufacturing standards. The specification mandates crimping pressures between 7-9 tons to create gas-tight connections, eliminating micro-gaps where corrosion thrives. Production includes ultrasonic cleaning to remove contaminants, followed by electroless tin plating for uniform coverage—critical for consistent performance across the lug’s contact surface. This process ensures the lugs can handle the 800V systems’ 500+ amp current without overheating.

Authoritativeness: Aligning with Global Safety Standards

These innovations align with evolving regulatory frameworks for high-voltage EV infrastructure. China’s updated GB/T 5095-2025 standard, released in March 2025, explicitly requires “corrosion-resistant, high-conductivity grounding terminals” for charging systems operating above 600V, with tinned copper cited as a recommended solution. The standard notes that proper grounding reduces fault current response time by up to 30%, a critical factor in preventing electrical hazards.

Industry leaders are prioritizing these components. “In 800V mega-watt charging, grounding reliability directly impacts system uptime and user safety,” says Mark Thompson, Chief Engineer for Tesla’s Supercharger Program. “We’ve standardized on UL486E tinned copper lugs in our latest stations because they outperform alternatives in accelerated aging tests, especially in coastal and industrial environments with high sulfur exposure.”

Trustworthiness: Verified by Third Parties and Real-World Adoption

Independent testing validates the performance claims. SGS conducted 1,200-hour salt spray tests simulating coastal and industrial environments, finding that tinned copper lugs showed zero visible corrosion and just a 2% resistance increase. In contrast, bare copper lugs corroded significantly, with a 53% resistance spike. Access the full SGS test report here.

Real-world adoption tells a similar story. Star Charge, one of Asia’s largest EV charging operators, upgraded 800 of its 800V stations to tinned copper lugs in 2024. Post-upgrade data shows a 68% drop in grounding-related faults, with mean time between failures (MTBF) rising from 127 days to 451 days—directly boosting operational efficiency and customer satisfaction.

Technical Deep Dive: Comparing Plating Materials for High-Voltage Grounding

| Plating Type | Contact Resistance Coefficient (K) | 1200hr Salt Spray Resistance | Cost vs. Bare Copper |

|---|---|---|---|

| Tin (5-10μm) | 1.2 | 98% protection | +18% |

| Silver (2-3μm) | 1.0 | 83% protection | +130% |

| Nickel (8-10μm) | 1.7 | 91% protection | +45% |

| Bare Copper | 1.6 | 32% protection | Base |

Thermal simulations using COMSOL Multiphysics further illustrate the risk of subpar lugs: a 15°C temperature rise in bare copper lugs (due to resistance) can cause adjacent insulation layers to degrade, reducing their dielectric strength by 40% over six months. Tinned copper lugs, by maintaining stable resistance, prevent this degradation chain.